Magnetizers are specialized devices designed to manipulate the magnetic properties of materials. They operate on the principles of electromagnetism, primarily through the use of electromagnetic coils. When an electric current flows through these coils, a magnetic field is generated, which, in turn, induces the alignment of atomic magnets within the material. This alignment process results in the material becoming magnetized, making it either a permanent magnet or temporarily magnetized for specific applications. Magnetizers find widespread use in industries ranging from manufacturing to electronics, where precise control over magnetization is paramount.

| Feature | Permanent Magnetizer | Electromagnetic Magnetizer | Pulse Magnetizer | Continuous Magnetizer |

|---|---|---|---|---|

| Type of Magnetization | Permanent | Variable (can be permanent or temporary) | Temporary | Temporary |

| Magnetic Field Control | Fixed magnetic field strength | Variable magnetic field strength | Variable, high-intensity pulses | Continuous magnetic field |

| Common Applications | Creating permanent magnets, e.g., in electric motors | Magnetizing and demagnetizing various materials | Scientific experiments, material testing | Mass production environments, e.g., automotive industry |

| Precision Magnetization | High precision | Variable precision | High precision | Variable precision |

| Power Consumption | Low power consumption | Moderate power consumption | High power consumption | Moderate power consumption |

| Size and Portability | Often large and stationary | Variable in size and portability | Compact and portable | Typically large and stationary |

| Versatility | Limited to permanent magnetization | Suitable for a wide range of magnetization tasks | Limited to specific high-intensity applications | Suitable for mass production magnetization |

| Cost | Moderate to high cost | Moderate cost | Moderate to high cost | Moderate cost |

Contents

What are the magnetizers work?

In the realm of modern science and industry, the functioning of magnetizers stands as a testament to human ingenuity harnessed to unlock the secrets of magnetism. But what precisely are magnetizers, and how do they work their magnetic magic? This inquiry into the depths of magnetizer functionality unveils the intricate interplay of electromagnetic forces, materials science, and industrial innovation.

Magnetizers are ingenious devices engineered to manipulate the magnetic properties of materials, catering to a diverse spectrum of applications across numerous sectors. From crafting powerful permanent magnets in the realm of manufacturing to fine-tuning magnetic sensors for sensitive electronics, these marvels of engineering have woven themselves into the very fabric of our technological advancement.

How Do Magnetizers Function?

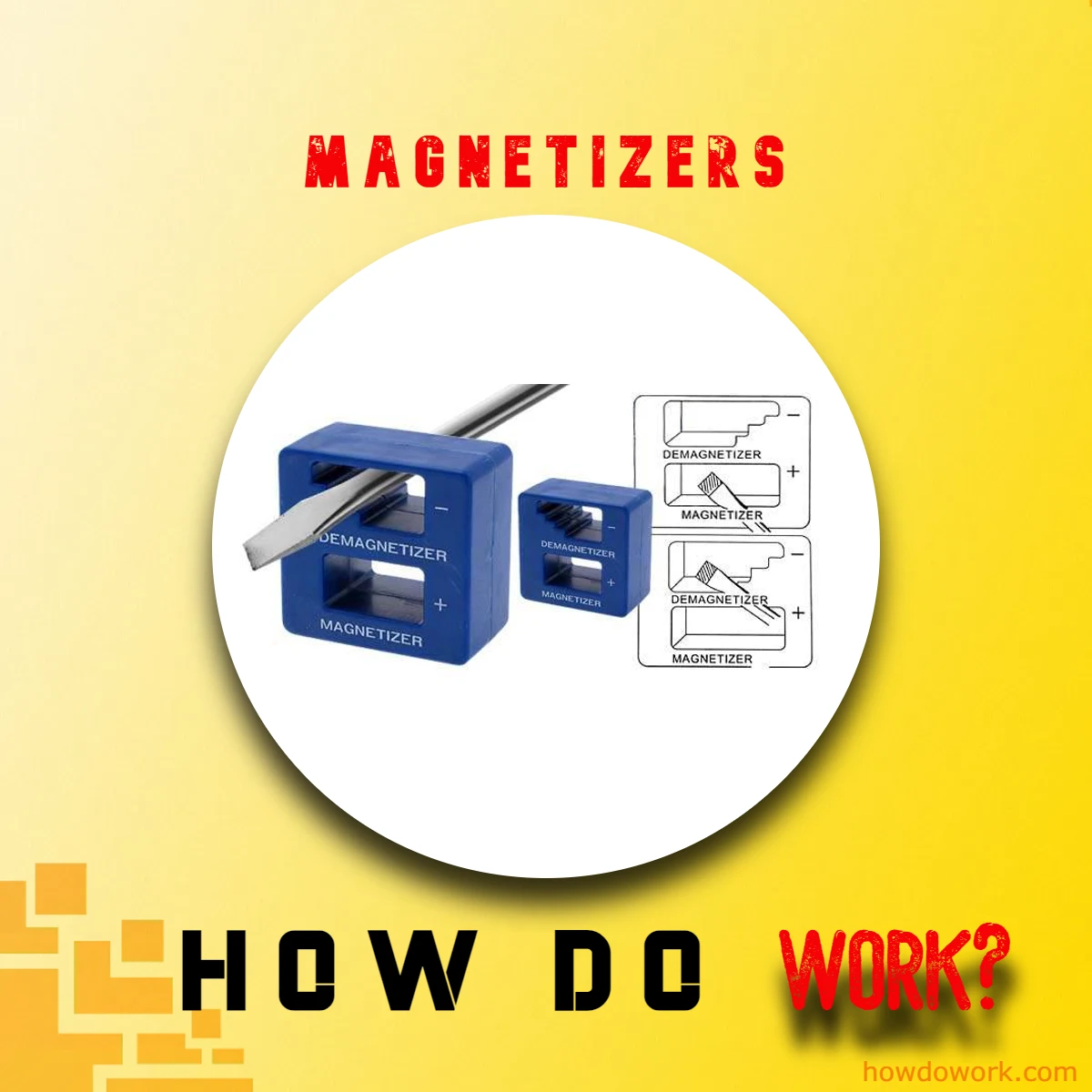

Magnetizers, often referred to as demagnetizers or magnetizing machines, serve a pivotal role in manipulating the magnetic properties of materials. They’re widely employed in industries ranging from electronics to manufacturing, offering a spectrum of applications.

The Core Principle

At its core, a magnetizer operates based on the principles of electromagnetism. It involves applying a magnetic field to a material, either to magnetize it or demagnetize it. The most common scenario is magnetizing an object, turning it into a permanent magnet.

Electromagnetic Coils

The heart of a magnetizer lies in its electromagnetic coils. These coils are typically made of copper wire wound around a core, often composed of iron. When an electric current flows through these coils, it generates a magnetic field.

Magnetic Domains Alignment

Now, let’s dive into the nitty-gritty of how magnetization occurs. Most materials are comprised of tiny atomic magnets known as magnetic domains. In their natural state, these domains have random orientations, resulting in little to no net magnetization.

When a material is placed within the magnetic field generated by the electromagnetic coils of the magnetizer, something remarkable happens. The magnetic field induces a torque on the atomic magnets within the material, causing them to align in the direction of the field. This alignment process results in a net magnetization of the material.

Types of Magnetizers

Magnetizers come in various forms, each designed for specific applications. Here, we’ll explore some of the common types:

1. Permanent Magnetizers

Permanent magnetizers are used to create permanent magnets from materials that are not naturally magnetic. This type of magnetizer is frequently employed in industries that require strong permanent magnets, such as the production of electric motors or generators.

2. Electromagnetic Magnetizers

Electromagnetic magnetizers, as the name suggests, utilize an electromagnetic coil to generate a magnetic field. They are versatile and can be used for both magnetization and demagnetization processes. These are often found in the electronics industry, where precise magnetization is crucial.

3. Pulse Magnetizers

Pulse magnetizers are specialized devices that generate short bursts of high-intensity magnetic fields. They are commonly used in research and development settings for various applications, including material testing and scientific experiments.

4. Continuous Magnetizers

Continuous magnetizers, on the other hand, provide a continuous magnetic field. They are favored in mass production environments, where efficiency and speed are paramount, such as in the automotive industry for magnetizing components like sensors and actuators.

Applications of Magnetizers

Now that we’ve established how magnetizers work and the different types available, let’s explore the myriad applications that benefit from these devices.

1. Manufacturing and Engineering

In the realm of manufacturing, magnetizers play a pivotal role in producing a wide range of products. From magnetizing components in the automotive industry to creating powerful magnets for industrial machinery, these devices are indispensable for ensuring the functionality and efficiency of various mechanical systems.

2. Electronics

Magnetizers are essential tools in the electronics industry. They are used to magnetize components like magnetic sensors, which are crucial for detecting position and motion in devices such as smartphones, gaming controllers, and navigation systems. Magnetization precision is paramount in this context, as it directly impacts the performance of these sensitive electronic components.

3. Research and Development

In research and development (R&D) environments, magnetizers enable scientists and engineers to explore new materials and study their magnetic properties. Researchers use pulse magnetizers to subject materials to intense magnetic fields, allowing them to observe how different materials react under extreme conditions. This is invaluable for advancing our understanding of magnetism and developing cutting-edge technologies.

4. Healthcare

Believe it or not, magnetizers even have a role in healthcare. Magnetic resonance imaging (MRI) machines, commonly used for medical diagnoses, rely on powerful magnets to create detailed images of the body’s internal structures. These magnets need to be precisely controlled, and magnetizers are used in their production and maintenance.

5. Security and Defense

In the realm of security and defense, magnetizers are employed to create specialized magnets used in various applications, including magnetic locks and sensors. These devices are crucial for ensuring the security of sensitive areas and equipment.

The Science Behind Demagnetization

While we’ve primarily focused on magnetization, demagnetization is another critical aspect of magnetizer functionality. Demagnetization is the process of reducing or eliminating the magnetization of a material, returning it to a non-magnetic state.

Demagnetization is achieved by subjecting a material to a magnetic field in the opposite direction of its magnetization. This disrupts the alignment of magnetic domains, causing them to return to their random orientations. Demagnetizers are commonly used in industries where precise demagnetization is required, such as in the production of credit cards and magnetic stripe data storage devices.

Advanced Magnetization Techniques

Magnetization is not just a one-size-fits-all process. Depending on the application and the material involved, advanced techniques have been developed to achieve specific magnetization goals.

1. Gradient Magnetization

In certain applications, it’s essential to have varying levels of magnetization within a single object. This is where gradient magnetization comes into play. Magnetizers equipped with advanced controls can create magnetic gradients, allowing for precise control over the strength of the magnetization at different points within a material. This technique finds use in sensors and devices requiring fine-tuned magnetic sensitivity.

2. Pulsed Field Magnetization

Pulsed field magnetization involves applying rapidly changing magnetic fields to materials. This technique is commonly used in the production of high-performance magnets for scientific research and aerospace applications. Pulsed field magnetization allows for the creation of exceptionally strong magnets that can withstand extreme conditions.

3. Magnetostriction Magnetization

Magnetostriction is a phenomenon where the shape of a material changes when subjected to a magnetic field. Some materials exhibit this property, and it can be harnessed for specialized magnetization purposes. Magnetostriction magnetization techniques are used in devices like ultrasonic transducers and sensors.

4. Quenching and Annealing

In certain situations, magnetized materials may need further treatment to optimize their properties. Quenching and annealing involve subjecting magnetized materials to specific temperature and magnetic field conditions to enhance their magnetic characteristics. This process is particularly useful in the production of high-quality permanent magnets.

The Future of Magnetizers

As technology continues to advance, the future of magnetizers holds exciting possibilities. Here are some trends and developments that we can anticipate:

1. Miniaturization and Portability

Advancements in materials and electronics are leading to the miniaturization of magnetizers. Portable and handheld magnetizers are becoming more common, allowing for on-the-spot magnetization and demagnetization tasks. This trend is beneficial across various industries, from electronics repair to field research.

2. Automation and Robotics Integration

The integration of magnetizers into automated manufacturing and assembly lines is on the rise. Robots equipped with magnetization capabilities can perform tasks with precision and consistency, reducing human error and increasing efficiency. This trend is particularly evident in the automotive and electronics sectors.

3. Enhanced Magnetic Materials

Materials science continues to evolve, leading to the development of new magnetic materials with enhanced properties. Magnetizers will need to adapt to accommodate these novel materials and provide specialized magnetization processes to fully leverage their potential.

4. Green Magnetization Technologies

With an increasing emphasis on sustainability and environmental impact, there is a growing interest in developing eco-friendly magnetization techniques. This includes reducing energy consumption during magnetization processes and exploring alternatives to traditional magnetizing materials.

5. Quantum Magnetization

In the realm of quantum computing and quantum technologies, magnetizers are poised to play a critical role. Quantum magnetization techniques may be developed to manipulate the quantum states of materials, opening up entirely new avenues for research and applications in quantum information science.

Magnetizers: Enablers of Innovation

In the grand scheme of technological progress, magnetizers are often unsung heroes. They quietly facilitate innovations across diverse industries, from healthcare to aerospace, electronics to research. As we look ahead to the future, it’s clear that these devices will continue to evolve, adapting to the ever-changing needs of science and industry.

So, whether you’re a scientist pushing the boundaries of magnetic materials or a manufacturer striving for precision in your products, remember that magnetizers are your partners in harnessing the power of magnetism, paving the way for a brighter, more magnetic future.

Why do magnetizers fail?

Magnetizers can fail for various reasons, and understanding these potential issues is crucial for maintaining their functionality and preventing breakdowns. Here are some common reasons why magnetizers may fail:

Overheating:

Magnetizers often generate magnetic fields by passing electrical current through coils. If the device is operated continuously for extended periods without proper cooling mechanisms, it can overheat. Overheating can lead to damage to the coils or other critical components.

Electrical Failures:

Electrical components, such as capacitors, resistors, or diodes, can degrade over time or experience sudden failures. These components are essential for regulating the electrical current and ensuring the proper functioning of the magnetizer.

Coil Damage:

The coils used in magnetizers are susceptible to physical damage, such as abrasion, wear and tear, or even accidental impact. Damaged coils can disrupt the magnetic field generation process.

Power Supply Issues:

Irregularities in the power supply, such as voltage spikes or fluctuations, can adversely affect the magnetizer’s operation. Inconsistent power can result in magnetization processes that are not up to specifications or even damage the device.

Contamination:

Dust, dirt, or other contaminants can accumulate on the components of a magnetizer over time. This buildup can interfere with the device’s operation, reduce its efficiency, or cause electrical shorts.

Moisture and Corrosion:

Magnetizers exposed to moisture or corrosive environments may suffer from corrosion or rust. This can lead to degradation of the materials and electrical connections, affecting the device’s performance.

Aging:

Like any mechanical or electrical device, magnetizers can simply wear out over time. Components may become less reliable, and the overall efficiency of the device can diminish.

Misuse or Operator Errors:

Improper use, mishandling, or operator errors can lead to magnetizer failures. For example, exceeding the device’s operational limits, applying incorrect settings, or not following maintenance procedures can all contribute to failures.

Software or Control System Issues:

In modern magnetizers, software and control systems play a crucial role in managing the magnetization process. Software glitches, programming errors, or issues with control interfaces can result in malfunctions.

Environmental Factors:

Environmental conditions, such as extreme temperatures or humidity, can impact the reliability and longevity of magnetizers. Devices used in harsh environments may require additional protection and maintenance.

Lack of Maintenance:

Regular maintenance is essential to ensure the proper functioning of magnetizers. Neglecting routine inspections, cleaning, and component replacement can lead to gradual deterioration and eventual failure.

Component Wear:

Components like switches, relays, and connectors can wear out with frequent use. Worn-out components can cause intermittent failures or complete malfunction of the magnetizer.

To prevent magnetizer failures, it is essential to follow the manufacturer’s maintenance guidelines, conduct regular inspections, and address any issues promptly. Additionally, using the magnetizer within its specified operating parameters and providing adequate cooling and power stability can help prolong its lifespan and ensure reliable performance.

FAQs

Magnetizers operate by using electromagnetic coils to generate a magnetic field. When an electric current flows through these coils, it induces the alignment of atomic magnets within a material. This alignment process results in the material becoming magnetized, either permanently or temporarily, depending on the application.

Common types of magnetizers include permanent magnetizers, electromagnetic magnetizers, pulse magnetizers, and continuous magnetizers. Each type has its specific applications and mechanisms for generating magnetic fields.

Magnetizers are used in various industries, including manufacturing, electronics, research and development, healthcare, and security. They are employed for tasks such as creating permanent magnets, magnetizing electronic components, conducting scientific experiments, and producing magnetic resonance imaging (MRI) machines.

Yes, magnetizers can also be used for demagnetization. Demagnetizers subject materials to a magnetic field in the opposite direction of their magnetization, returning them to a non-magnetic state. This process is essential for applications where precise demagnetization is required.

To prevent overheating, magnetizers are often equipped with cooling mechanisms, such as fans or heat sinks. Proper ventilation and temperature monitoring help maintain the device’s operational temperature within safe limits.

Magnetizer failures can result from various factors, including overheating, electrical failures, coil damage, power supply issues, contamination, moisture and corrosion, aging, misuse, software or control system issues, and environmental conditions.

To prolong the lifespan of a magnetizer, it is essential to follow manufacturer’s maintenance guidelines, conduct regular inspections, provide adequate cooling and power stability, and ensure proper use within specified operating parameters.

The future of magnetizers holds exciting possibilities, including miniaturization, automation and robotics integration, enhanced magnetic materials, green magnetization technologies, and quantum magnetization techniques, all of which will contribute to advancing various industries and technologies.

Read More: