Knock sensors, a vital component in modern engines, work by detecting engine knock or detonation. These sensors, typically equipped with piezoelectric crystals or resonant frequency circuits, monitor the engine’s vibrations and sounds. When they sense any irregularities or knocking, they transmit this data to the engine control unit (ECU). The ECU, acting as the engine’s brain, then adjusts critical parameters like ignition timing and fuel delivery to prevent engine damage and optimize performance. In essence, knock sensors ensure that your engine operates at its peak efficiency and longevity by continuously fine-tuning the combustion process.

| Aspect | Piezoelectric Knock Sensors | Resonant Frequency Knock Sensors |

|---|---|---|

| Sensing Principle | Use piezoelectric crystals to detect vibrations caused by knocking. | Rely on a resonant frequency circuit that vibrates at a specific frequency. |

| Detection Mechanism | Generate a voltage signal in response to engine vibrations. | Detect changes in the resonant frequency caused by knocking. |

| Signal Sent to ECU | Send a voltage signal to the Engine Control Unit (ECU) for analysis. | Transmit a signal to the ECU, indicating changes in resonance. |

| Common Material | Quartz or similar piezoelectric materials. | Various materials used for resonance, often with a tuned resonator. |

| Sensitivity to Knock | Highly sensitive and can detect the intensity of knocking. | Generally sensitive but may have limitations in detecting very light knocking. |

| Common in Modern Vehicles | Yes, piezoelectric knock sensors are widely used in modern vehicles. | Less common in modern vehicles but still found in some older models. |

| Advantages | High sensitivity, accuracy, and ability to detect varying levels of knock. | Simplicity and durability in some applications. |

| Disadvantages | Can be more fragile due to the piezoelectric crystals. | May not provide as precise information as piezoelectric sensors. |

| Tuning and Calibration | Require calibration to specific engine characteristics. | May be less specific to engine characteristics and may not require as much tuning. |

Contents

- What are the knock sensors work?

- The Role of Knock Sensors

- Types of Knock Sensors

- The Importance of Knock Sensors

- Knock Sensors in Action

- Knock Sensors: A Troubleshooting Tool

- Knock Sensors and Engine Tuning

- Maintaining Knock Sensor Health

- Why do Knock Sensors fail?

- Recognizing Knock Sensor Failure

- What to Do When Knock Sensor Failure Occurs

- Advanced Knock Sensor Technologies

- The Future of Knock Sensors

- Knock Sensors in Other Applications

- Wrapping Up

- FAQs

What are the knock sensors work?

In the intricate realm of automotive engineering, where precision and performance coalesce, lie the inconspicuous yet paramount components known as knock sensors. These unassuming devices play a pivotal role in safeguarding the heart of your vehicle – the engine. But how, you may wonder, do knock sensors work their magic beneath the hood? The answer to this question unravels a tale of technological sophistication and mechanical vigilance, one that every car enthusiast and conscientious driver should comprehend.

These sensors, equipped with piezoelectric crystals or resonant frequency circuits, listen intently for the faintest echoes of engine knock – a telltale sign of premature ignition or irregular combustion. When detected, they swiftly relay this information to the engine control unit (ECU), the cerebral cortex of your vehicle, which, in turn, orchestrates a choreography of adjustments. These adjustments, often imperceptible to the driver, encompass finely-tuned alterations in ignition timing, fuel delivery, and air-to-fuel ratios. The ultimate objective? To ensure that each combustion event occurs with meticulous precision, delivering power, efficiency, and longevity to your engine.

The Role of Knock Sensors

So, what exactly is a knock sensor, and why should you care about it? Well, let’s start by explaining what “knocking” means in the context of an engine. Knocking, also known as detonation, is a phenomenon that occurs when the air-fuel mixture inside a cylinder ignites prematurely or unevenly. This can result in a distinctive knocking sound and, more importantly, can cause severe damage to your engine over time.

Knocking happens due to various factors, including low-quality fuel, high engine temperatures, or incorrect ignition timing. To prevent this destructive phenomenon and protect your engine, knock sensors come into play.

Detecting Engine Knock

Knock sensors are like the ears of your engine – they listen closely for any signs of knocking or pinging. Here’s how they work their magic:

- Piezoelectric Sensing: Most modern knock sensors use a piezoelectric crystal to do their job. When the engine produces vibrations or knocking sounds, these vibrations reach the sensor. The crystal inside the sensor generates a voltage in response to these vibrations. This voltage is then sent to the engine control unit (ECU).

- Voltage Signal Analysis: The ECU is the brain of your vehicle’s engine management system. It continuously monitors the voltage signals from the knock sensor. If the ECU detects unusual voltage spikes or patterns that indicate knocking, it knows there’s a problem.

- Adjusting Ignition Timing: Once the ECU identifies knocking, it takes action. One of the primary ways it mitigates knocking is by adjusting the ignition timing. By retarding or advancing the timing, the ECU can ensure that the air-fuel mixture ignites at the optimal moment, preventing knocking.

Why Timing Matters

Now, you might be wondering, why is ignition timing so crucial? Well, the timing of the spark plug firing determines when the air-fuel mixture combusts. If it happens too early (pre-ignition) or too late, it can lead to knocking, reduced power, and increased emissions. Here’s a bit more detail on how timing affects your engine’s performance:

- Pre-Ignition: When the spark plug fires too early, it can cause the air-fuel mixture to ignite while the piston is still moving upward in the compression stroke. This creates a sudden increase in pressure and temperature, leading to knocking.

- Late Ignition: Conversely, if the spark plug fires too late, the combustion may occur when the piston is already moving down the power stroke. This results in wasted energy and reduced engine efficiency.

By continuously monitoring and adjusting the ignition timing based on feedback from the knock sensor, your engine operates at its peak performance, ensuring a smooth and efficient ride.

Types of Knock Sensors

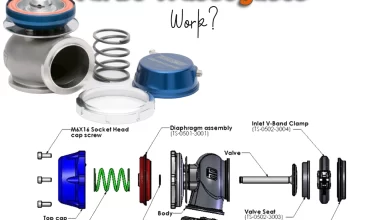

Knock sensors come in different shapes and sizes, each with its own way of sensing engine knock. Let’s explore the two primary types:

1. Piezoelectric Knock Sensors

Piezoelectric knock sensors are the most common type found in modern vehicles. These sensors use a piezoelectric crystal, usually made of quartz, to detect engine vibrations caused by knocking. When these vibrations occur, the crystal generates a voltage signal that is proportional to the intensity of the knock. This signal is then sent to the ECU for analysis and adjustment of the ignition timing.

2. Resonant Frequency Knock Sensors

Resonant frequency knock sensors are an older technology but are still in use in some vehicles. Instead of a piezoelectric crystal, they use a resonant frequency circuit that vibrates at a specific frequency. When knocking occurs, it disrupts this resonant frequency, causing a change in voltage that is detected by the ECU. While less common today, they are still effective at preventing engine damage from knocking.

The Importance of Knock Sensors

Now that we’ve covered how knock sensors work and the different types available, you might be wondering why they are so crucial. Well, let’s break down their importance into a few key points:

- Engine Protection: Knock sensors are like your engine’s guardian angels. By detecting and preventing knocking, they protect vital engine components from damage. Without knock sensors, your engine could suffer from severe wear and tear, leading to costly repairs.

- Improved Fuel Efficiency: Knocking not only damages your engine but also reduces fuel efficiency. When the air-fuel mixture ignites at the wrong time, you’re wasting fuel and getting less mileage out of every gallon. Knock sensors help optimize combustion for better gas mileage.

- Emission Control: Modern vehicles must meet strict emissions standards. Knock sensors play a role in reducing emissions by ensuring that combustion is as clean and efficient as possible. This helps keep our air cleaner and reduces the environmental impact of driving.

- Enhanced Performance: Knock sensors aren’t just about preventing problems; they can also enhance your engine’s performance. By fine-tuning the ignition timing, they help deliver more power and smoother acceleration, giving you a better driving experience.

- Longevity: A well-protected engine is likely to have a longer lifespan. Knock sensors contribute to the longevity of your vehicle by preventing premature wear and tear caused by knocking.

Knock Sensors in Action

To give you a better idea of how knock sensors work in real-world scenarios, let’s walk through an example:

Imagine you’re cruising down the highway, and you decide to step on the gas pedal for a burst of acceleration. This action prompts the engine to deliver more power by injecting more fuel and adjusting the ignition timing.

As you accelerate, the engine control unit (ECU) constantly receives data from various sensors, including the knock sensor. If the knock sensor detects any hint of knocking due to the increased engine load, it immediately sends a signal to the ECU.

The ECU, with its lightning-fast processing power, takes this signal and makes lightning-quick adjustments. It might slightly retard the ignition timing to ensure the air-fuel mixture ignites precisely when it should, eliminating any knocking.

All of this happens in a matter of milliseconds, and you, the driver, experience a smooth and powerful acceleration without any audible knocking or loss of performance.

Knock Sensors: A Troubleshooting Tool

Apart from their primary role in preventing engine knock, knock sensors can also be valuable troubleshooting tools for mechanics and DIY enthusiasts. When a vehicle exhibits performance issues or unusual sounds, the knock sensor data can provide critical diagnostic information.

For instance, if your engine is misfiring, idling roughly, or experiencing a drop in fuel efficiency, the knock sensor data can help pinpoint the problem. It may indicate issues with fuel quality, carbon buildup, or even a failing sensor itself. Mechanics can access this data using specialized diagnostic tools, allowing them to address problems more effectively.

Knock Sensors and Engine Tuning

Now that we’ve covered the basics of how knock sensors work and their importance, let’s delve into a more advanced topic: engine tuning. Engine tuning involves optimizing your vehicle’s performance, and knock sensors play a significant role in this process.

1. Performance Tuning

Performance enthusiasts often seek ways to extract more power from their engines. This can involve modifications like installing a high-flow exhaust, upgrading the air intake, or even remapping the engine’s computer. However, when you make these modifications, you need to consider the impact on the engine’s air-fuel mixture and ignition timing.

This is where knock sensors come into play. As you make changes to your vehicle’s setup, the knock sensor helps ensure that the engine operates within safe parameters. If any modifications result in knocking, the sensor will alert the ECU, which can then make adjustments to prevent engine damage.

2. Aftermarket ECU Tuning

Some car enthusiasts take engine tuning to the next level by installing aftermarket engine control units (ECUs). These specialized ECUs offer more advanced features and greater control over engine parameters, including ignition timing. When using an aftermarket ECU, it’s essential to pay close attention to knock sensor data.

Enthusiasts and tuners can use this data to fine-tune the engine for optimal performance. By carefully adjusting the ignition timing and air-fuel ratios, they can achieve higher power outputs while still ensuring the engine operates safely and reliably.

Maintaining Knock Sensor Health

Now that you’re well-versed in the world of knock sensors, it’s essential to know how to keep them in top shape. After all, a malfunctioning knock sensor can lead to engine damage and decreased performance. Here are some tips for maintaining knock sensor health:

- Use Quality Fuel: Low-quality or contaminated fuel can lead to knocking. Using high-quality, clean fuel with the appropriate octane rating for your vehicle can reduce the risk of knocking and help your knock sensor perform optimally.

- Regular Maintenance: Routine vehicle maintenance, including spark plug replacements and air filter changes, can help keep your engine running smoothly. A well-maintained engine is less likely to experience knocking.

- Avoid Overheating: Overheating can contribute to engine knocking. Make sure your vehicle’s cooling system is in good working order to prevent excessive heat buildup in the engine.

- Check for Fault Codes: If you suspect an issue with your knock sensor, consider using an OBD-II scanner to check for fault codes. These codes can provide insights into sensor problems or other issues that may affect sensor performance.

- Professional Inspection: If you experience persistent knocking, reduced performance, or poor fuel efficiency, it’s a good idea to have your vehicle inspected by a professional mechanic. They can diagnose and address any knock sensor-related issues.

Why do Knock Sensors fail?

Knock sensors are dependable components of an engine’s management system, but like any part, they can sometimes fail. Let’s delve into the reasons behind knock sensor failure, how to recognize it, and what you can do when it happens.

1. Age and Wear

Just like any other electronic component, knock sensors can deteriorate over time due to normal wear and tear. Over the years, exposure to temperature fluctuations, vibrations, and other environmental factors can weaken the sensor’s internal components. This gradual aging can result in reduced sensitivity or, in severe cases, complete sensor failure.

2. Physical Damage

Knock sensors are typically located on or near the engine block, making them vulnerable to physical damage. Accidental impacts, rough handling during repairs, or even debris from the road can harm the sensor. Cracked or damaged sensor housings can compromise their ability to detect knocking accurately.

3. Contaminants and Corrosion

Engines are not always pristine environments. Moisture, oil leaks, and various contaminants can find their way to the knock sensor. This exposure can lead to corrosion of the sensor’s electrical connectors or the sensor itself. Corrosion can disrupt the sensor’s ability to generate and transmit signals effectively.

4. Wiring and Connector Issues

Knock sensors are connected to the engine control unit (ECU) via wiring harnesses and connectors. Over time, these wires can fray, become damaged, or develop electrical faults. If the wiring or connectors fail, it can prevent the knock sensor from transmitting data to the ECU, effectively rendering it useless.

5. Faulty ECU or Power Supply

Sometimes, the issue may not be with the knock sensor itself but with the components it interacts with. A malfunctioning ECU or irregular power supply can lead to inaccurate readings or the failure of the sensor’s signals to be properly interpreted.

6. Poor Quality Fuel

The quality of fuel you use in your vehicle can indirectly affect the lifespan of your knock sensor. Low-quality or contaminated fuel may increase the likelihood of engine knocking. Frequent knocking can put extra strain on the knock sensor, potentially leading to premature failure.

7. Engine Detonation

In some cases, severe engine detonation or knocking events can overload and damage the knock sensor. This typically happens when engine conditions are excessively harsh or when the sensor has been neglected for an extended period.

Recognizing Knock Sensor Failure

Detecting knock sensor failure can be challenging since it doesn’t always trigger a check engine light. Here are some common signs that your knock sensor may be malfunctioning:

- Reduced Engine Performance: A faulty knock sensor may cause the ECU to retard ignition timing as a precaution, resulting in reduced engine power and sluggish acceleration.

- Poor Fuel Economy: Ignition timing adjustments made by the ECU to compensate for a failing knock sensor can lead to increased fuel consumption.

- Engine Misfires: If the sensor sends incorrect data to the ECU, it may lead to engine misfires or rough idling.

- Check Engine Light: While it’s not guaranteed, a failing knock sensor can sometimes trigger a check engine light. If it does, you should have the vehicle’s diagnostics checked immediately.

What to Do When Knock Sensor Failure Occurs

If you suspect or confirm that your knock sensor has failed, it’s essential to address the issue promptly to prevent further damage to your engine and restore optimal performance. Here’s what you can do:

- Diagnostic Check: Use an OBD-II scanner to read any fault codes. If the scan reveals a knock sensor-related code, it’s a clear indication that the sensor needs attention.

- Inspect Wiring and Connectors: Check the wiring and connectors leading to the knock sensor for damage or corrosion. Replace any compromised components.

- Replace the Knock Sensor: In most cases, replacing a faulty knock sensor is the best course of action. Consult your vehicle’s service manual or a professional mechanic to determine the exact location of the sensor and the replacement procedure.

- Quality Fuel: Ensure you’re using high-quality, clean fuel to reduce the risk of engine knocking and subsequent sensor damage.

- Professional Assistance: If you’re not comfortable diagnosing or replacing the sensor yourself, seek the assistance of a qualified mechanic or technician. They can accurately diagnose the issue and perform the necessary repairs or replacements.

In conclusion, while knock sensors are relatively robust components, they can fail due to factors like age, physical damage, contamination, and more. Recognizing the signs of knock sensor failure and addressing the issue promptly is crucial to maintaining your vehicle’s performance and preventing potential engine damage.

Advanced Knock Sensor Technologies

As technology continues to evolve, so do knock sensor technologies. Manufacturers are constantly striving to improve the accuracy and responsiveness of these sensors. Here are some advanced knock sensor technologies that are making their way into modern vehicles:

1. Wideband Knock Sensors

Wideband knock sensors are designed to provide a more detailed and precise analysis of engine knock. Unlike traditional knock sensors that simply detect the presence of knocking, wideband sensors can measure the severity and frequency of knocking events. This information allows the engine control unit to make even more precise adjustments to ignition timing and fuel delivery, resulting in improved performance and efficiency.

2. Knock Sensor Arrays

In some high-performance and luxury vehicles, you may find knock sensor arrays. Instead of relying on a single knock sensor, these systems use multiple sensors strategically placed throughout the engine. This multi-sensor approach provides a comprehensive view of engine knock across all cylinders, allowing for even more precise adjustments to prevent knocking.

3. Knock Control Strategies

Modern vehicles often employ advanced knock control strategies that go beyond simple ignition timing adjustments. These strategies may include cylinder deactivation, fuel enrichment, and variable valve timing adjustments. By combining these techniques with knock sensor data, engines can deliver optimal performance while maintaining reliability and efficiency.

The Future of Knock Sensors

As we look to the future, the role of knock sensors is likely to become even more critical. Here are some trends and developments that we can expect:

1. Integration with Artificial Intelligence

Artificial intelligence (AI) and machine learning are finding their way into automotive technology. In the future, knock sensors may work in tandem with AI systems to continuously adapt and optimize engine performance based on real-time data. This could lead to even more efficient and responsive engines.

2. Enhanced Diagnostics

Future knock sensors may offer advanced diagnostic capabilities, allowing them to not only detect knocking but also identify the root causes. This information could be invaluable for mechanics and engineers when troubleshooting engine issues.

3. Improved Materials

Advancements in materials science may lead to even more sensitive and durable knock sensor components. This could result in sensors that can withstand harsher conditions and provide even more accurate data.

Knock Sensors in Other Applications

While we’ve mainly focused on automotive applications, knock sensors have uses beyond just cars and trucks. Here are a few examples:

1. Aviation

In aircraft engines, knock sensors are critical for detecting detonation, which can be particularly dangerous at high altitudes. They help ensure the safety and reliability of aircraft engines.

2. Industrial Engines

Large industrial engines, such as those used in power generation or marine applications, also benefit from knock sensors. They help optimize engine performance and prevent damage in these heavy-duty settings.

3. Small Engines

Even small engines, like those in lawnmowers, chainsaws, and generators, can benefit from knock sensors. These sensors help improve efficiency and extend the lifespan of these smaller powerplants.

Wrapping Up

Knock sensors may be small and often overlooked, but they play a crucial role in the performance, longevity, and efficiency of engines across various applications. From your daily commute to the skies above and industrial powerhouses, these sensors are silently at work, ensuring engines run smoothly and safely.

So, the next time you start your car, remember that there’s more to it than meets the eye. Behind the scenes, your trusty knock sensor is doing its part to make your journey as smooth and trouble-free as possible.

FAQs

Engine knock, also known as detonation, is a phenomenon where the air-fuel mixture in an engine’s cylinder ignites prematurely or unevenly. It results in a knocking or pinging sound and can lead to severe engine damage over time. Knock is a concern because it can cause excessive wear and tear on engine components, reduce fuel efficiency, and increase emissions.

Knock sensors act as the “ears” of your engine. They detect vibrations and sounds associated with knocking and transmit this information to the engine control unit (ECU). The ECU then adjusts critical parameters such as ignition timing and fuel delivery to prevent knocking, ensuring smooth engine operation and longevity.

Piezoelectric knock sensors use piezoelectric crystals to detect engine vibrations caused by knocking and generate voltage signals. Resonant frequency knock sensors rely on a circuit that vibrates at a specific frequency and detects changes in resonance caused by knocking. Piezoelectric sensors are more common in modern vehicles due to their high sensitivity and accuracy, while resonant frequency sensors are less common but still effective in some applications.

Yes, a faulty knock sensor can negatively impact engine performance. When a knock sensor fails or provides inaccurate data, the ECU may respond by retarding ignition timing, which can lead to reduced power, decreased fuel efficiency, and increased emissions. It’s essential to address knock sensor issues promptly to maintain optimal engine performance.

Common signs of a malfunctioning knock sensor include reduced engine performance, poor fuel economy, engine misfires, and, in some cases, a check engine light. If you experience these symptoms, it’s advisable to have your vehicle’s diagnostics checked by a professional to identify and address any knock sensor-related problems.

Knock sensors can be replaced when they fail. However, it’s essential to use the correct replacement part for your vehicle’s make and model. While they don’t typically require calibration, the ECU may adapt to the new sensor over time. It’s always a good practice to consult your vehicle’s service manual or a professional mechanic for guidance on sensor replacement.

Read More: